The Problem:

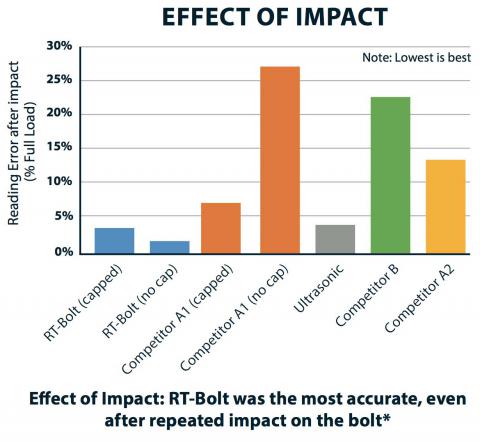

A refinery had continuous nuisance leakage from a bank of high temperature heat exchangers with 3/4” bolts. Assessment of the joint integrity revealed that an extremely high assembly bolt load (90% of yield) was required in order to ensure good joint integrity.

The Consequence:

Leakage of these joints was problematic for the re nery, requiring shutdown to retighten the joints and, on occasion, shutdown to replace the gaskets. The cost associated with these activities, and the risk to personnel were substantial.

Previous Fixes:

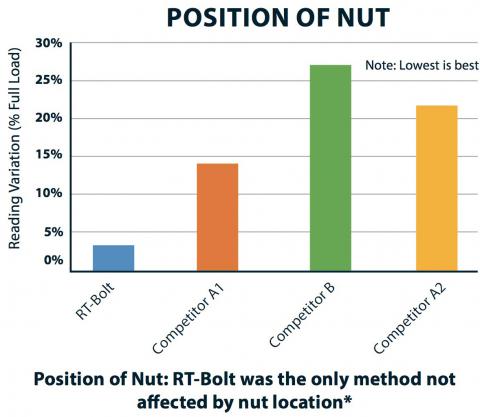

Other load indicating bolts had been used in the past, but due to the small diameter of the bolts and the larger bore of the device, these devices prevented tightening to as high an assembly bolt load as desired. They were also found to be poorly installed on occasion, with the nut being too many threads away from the end of the bolt, greatly reducing accuracy.

The RT-Bolt Solution:

RT-Bolts were machined into a set of 3/4 inch diameter A193-B16 bolts, in order to facilitate accurate assembly of the joint to 90% of yield and allow ongoing monitoring of the residual bolt load using the ceramic high temperature RT-Bolt gauges.

The Outcome:

The RT-Bolts worked well for assembly and the joints were brought online with no leakage issues. Online measurement of the bolt load indicated that some bolt relaxation or bolt yielding may have occurred, which will be investigated further once the joints are taken out of service.

Download: